Resources

CHECK OUT OUR VIDEOS - they might just answer your questions! Watch Product Videos

Need a FastFerment Manual? Download it Here

FAQs

1A. Where are my wall brackets?

1B. Where is my Hose Barb?

Wall brackets are located in the bottom of the box of your FastFerment under the cardboard insert. We pack them there to protect the conical from scratches.

Your hose barb is now located in the valve box, it's the same colour as the valve. The white one in the picture is an old model.

2. Does the FastFerment need to be covered or can it be left under fluorescent lighting?

The vessel is made from White HDPE Plastic. It keeps 90% of all light out and we have found this does not affect the quality of beer or wine.

3. What are the dimensions of the FastFerment in the Stand and Wall Mounts?

-

Height

On wall mounts from bottom of collection ball:

- To top of Airlock: 35.5", 90cm

- To top of Lid: 32", 81cm

In the Stand:

- To top of Airlock: 37", 94cm

- To top of Lid: 33.5", 85cm

-

Widths

- Bottom Ring of the Stand: 14" wide

- Top Ring of the Stand: 10" wide

- With Wall Mounting Bolts: 14.75", 37.5cm

- Without Wall Mounting Bolts (and max width in the Stand): 14.25", 36cm

4. Where are you located?

We ship out of our factory in Michigan.

5. Bottom collection ball volume?

700mL or 23.7oz

6. Do you ship to international locations?

We ship all over the world. Check out our Retailer Map to find your country

7. Do you make other sizes of FastFerment?

We make FastFerment in 3 different sizes - the 7.9 US Gallon / 30 L FastFerment, the 14 G / 53 L & the 3 G / 11.3 L versions.

8. Is the fluid volume on the side calculated with or without the valve open to the collection ball?

It is calculated with the valve CLOSED (only the contents of the vessel)

9. How do I use Grapes, Seeds, Tea, Chips and Other Large Ingredients in FastFerment

The FastFerment has a 1" valve to ensure that the conical design allows trub and sediment to fall into the collection ball without losing too much product. That said, larger items can clog the 1" valve so as a rule-of-thumb, we suggest any items larger than 0.5" should be put into our FastFerment Hop Filter accessory or a muslin bag and suspended into the FastFerment during fermentation (or whenever you would normally add these in). The muslin bag can be affixed to the inside of the lid with a very small hook or another trick is using fishing line to tie it and hang it out the side (while the lid is closed tight) for easy access to remove it.

10. Do you have wholesale pricing?

Yes please email us at: [email protected] or contact your wholesaler of other homebrew equipment.

11. Can you provide me with more information about the Thermowell and Thermometer?

The outside thread diameter is 1/2" NPT.

The Interior width where the thermometer is inserted is 9mm wide and 3" deep.

It is not threaded on the inside.

12. Do you need to dump and clean the collection ball out multiple times?

This can be pretty standard depending on what you are brewing and how heavy everything is. Some really heavy batches might need the ball to be purged 2, 3, or sometimes 4 times to get rid of sediment and trub. Make sure you have let the primary fermentation happen completely (7-12 days) before starting to purge the sediment and trub. It is best to let it sit overnight before you dump and clean the collection ball until all the sediment, trub, and yeast are cleared from the vessel. It takes time for everything to properly settle in the collection ball so letting it sit overnight is recommended.

13. When you reattach the collection ball and open the valve, will air be pulled back into the unit through the airlock?

When the collection ball is switched out and reattached, there will be a small amount of O2 sucked back into the unit. Our tests show it is around 20-40ml of O2 that is sucked back. However, there is no fluid from the airlock that is sucked into to the unit with the standard 3-Piece Airlock design that comes with each FastFerment. Thus, when using this standard airlock, you do not need to remove the airlock while switching and reattaching the collection ball. Everything that is fermenting will be safe.

14. What will happen with the air “O2” when you reattach the collection ball?

The air will quickly pass through the beer or wine but will not affect the taste in the long run.

When the valve is opened 700ml of O2 rushes through the liquid as it rises. When it reaches the top of the liquid it hits the head space that is filled with CO2. With O2 being lighter than CO2, the O2 now also rises through the CO2 and rests in the top of the head space. As fermentation continues it pushes the O2 through the airlock. The only time the O2 is in contact with the liquid is for 1.5 second while it passes through. The layer of C02 protects the wart/juice from being in contact with the O2 until it is all pushed out.

700ml of air (which is what the collection ball would contain unless you are in a complete O2 environment) contains ~147ml (21%) of oxygen and ~546ml of nitrogen that would be be mixing with (if your headspace hasn't been disturbed) ~9.5L of CO2.

If it miraculously mixed instantaneously with your headspace as it arrived, that headspace would now contain ~1.5% oxygen, which would be pushed out rather quickly as that's how the headspace is developed to begin with unless you are topping with CO2 before sealing the FF.

Of course, gasses don't mix instantaneously. If they did, when you farted, everyone in the room would smell it at the same time.

Besides, don't wineries sparge with nitrogen to get the O2 out?

FastBrewing believes there is almost nil chance of oxygen spoilage when switching the ball out, and they do point out that some fill the ball with distilled water or CO2 when switching if they do feel it is a risk.

The system is a little unconventional and if you are trying to follow every word in a beer or wine making book it will be hard to do with FastFerment. But it will make extremely good beer, wine, ciders, and meads.

15. Other idea’s/suggestions or thoughts on reattaching the collection ball?

Many forums online talk about purging the collection ball with either CO2 or distilled water before reattaching it. We think both of these choices are good. Sometime the CO2 is not readily available so distilled water is best. Simply filled the collection ball up with either of these when reattaching it. You might need to make adjustments to your batch size depending on how accurate you are keeping things. At our office we can not detect a taste difference.

16. Clogging Issues

Depending on what you are brewing in your FastFerment you might experience a clogged valve. This should only happen with very heavy brews that drop a lot of trub/sediment. Or if you put ingredients in that are larger than .75” in the diameter. Always use a Muslin Bag to add ingredients that are over .75” in diameter or that could expand to over .75” in diameter when placed in liquid. If you do experience a clog these two methods will easily help unclog your unit and have you back brewing in no time:

- The first way to deal with a clogged valve is to: Close the valve and unattached the collection ball. Dump and clean the Collection Ball out and reattach it. When you open the valve back up the air bubble that shoots up should dislodge the clog. To have the best results when doing this we suggest you find something fairly soft such as the palm of your hand or rubber spatula (do not use a hard object like a hammer) and knock the parts of the conical where the clog is at the same time the air bubble is passing through. Near the bottom of the conical or on the valve is best but be gentle to ensure you do not damage your unit. Once the clog is dislodged let sit overnight before you dump and clean the collection ball out. It takes time for everything to properly settle in the collection ball. If this does not work use #2.

- Stick something down into the clog like a plastic rod to push the clog through. Be careful to ensure you do not scratch the inside of the conical or valve if having to perform this.

17. Where are the quick disconnects?

After doing a lot of research into the cam lock fitting release system we decided the Union release system would be better for a number of reasons.

- Previous V Vessel customers said that the cam lock fittings and seals wear out over time. The Union design will hold up better with less seals and working parts to wear out.

- The cam lock system adds about 2" of height to the system. One of the biggest requests we have is to make it as compact as possible so the Union was the obvious choice.

- The cam lock system requires additional space left under the unit to un-attach and re-attach it. This adds 2" in total height plus another 1.5" of access room need to un-attach and re-attach it. This means a total of 3.5" extra height is needed to accommodate the cam lock system.

- The cost of the cam locks and all the components needed to make the cam locks work would increase the cost much more than any benefit.

- We also took into consideration the time difference in using the camlocks compared to the union system. Overall the Union system might take 2-5 second longer to attach and reattach than the camlocks which we felt was fairly even overall.

18. I was wondering if there is a way to clean behind the ball on the Union Valve? It appears that is would require some type of spanner wrench, but I wanted to confirm before I disassembled the valve.

If you soak the valve in sanitizer overnight and open and close the valve during the soaking process it will clean the valve.

19. My FastFerment is leaking from the Thermowell or Collection Ball or Valve. What should I do?

The first thing to do is to ensure you have an adequate amount of Teak Tape on each threaded end. The Thermowell thread requires Teak Tape, the bottom thread on the large vessel requires Teak Tape and the thread on the collection ball requires Teak Tape. When putting on Teak Tape make sure to wrap the teak tape in a clockwise direction with 2-5 layers. Wrap the threads in 3-5 layers of teak tape and screw the adjoining parts together.

20. What temperatures can my FastFerment handle?

The conical vessel and parts can handle a max of 80 degrees celsius or 176 F

21. Where to buy accessories separately?

Contact your local homebrew supply store about individual accessories. Due to shipping and logistics we cannot make them available direct. But all our retail partners have access to FastFerment and Accessories so please follow up with them.

22. Should I follow the instructions on the Beer or Wine kit?

Yes - FastFerment is a vessel for making beer/wine/cider/mead so please always follow the directions for your beer/wine/cider/mead kit.

23. How do you stir the ingredients in FastFerment? What do you recommend using?

The best way to stir FastFerment is to use a long plastic rod or spoon that has been sanitized. Do not use metal as it will scrap the inside walls of the FastFerment. Always be gentle with the inside of your FastFerment.

24. How does the yeast harvesting work?

*These are just our suggestions. Not the Bible of yeast harvesting, please consult multiple sources*

- Keep valve closed and do not attach collection ball (do not pitch yeast immediately after adding wort/juice to FastFerment)

- Wait overnight or at least 5 hours

- Trub should have settled at the bottom of FastFerment

- Open ball valve and let trub fall out and discard it. Trub will be characterized by dark colour.

- Close ball valve once wort/juice starts to come out.

- Attach collection ball, open valve and pitch yeast.

- Wait 5-10 days for primary fermentation to be over. Collection ball should be filled with flocculated and dormant yeast ready to harvest.

- Close ball valve and disconnect collection ball.

- Pour contents of collection ball into a sanitized mason jar (or multiple jars depending on size).

- If there is trub at the bottom of collection ball do not add it to mason jar.

- Tightly seal mason jar closed and store in fridge as close to 32 F (0 C) as possible.

- Sanitize collection ball and reattach it to FastFerment.

- **optional: purge collection ball with C02 to minimize oxygen comes in contact with beer or wine.

- Open ball valve to start secondary fermentation.

- Small amount of yeast and trub will continue to collect in collection ball but this can all be discarded at the end of complete fermentation.

Using Harvested Yeast

- Use yeast within 2-3 weeks of harvesting

What type of yeast to harvest/do’s or don’ts/extra tips

- Try using reharvested yeast with a similar beer style to make consistent batches. Yeast will often contain a little flavour from previous batch.

- Always harvest from a low gravity and low hopped beer.

- Use pitching rate calculator for calculating viability of stored yeast

25. Have you thought about a warming/cooling blanket?

Our Insulated Jacket is now available at many retailers Find Insulated Jacket

25 A) How Does the Temperature Control Jacket Work?

Check out how it works here: How Jacket Works

25 B) What products can I use to heat my brew with the Temp Jacket?

We suggest using a BrewJacket - they make custom lids to fit right in the Fermenter - BrewJacket

25 C) Is the Insulated Jacket machine washable? Can I throw it in the dryer?

No. Since the materials are not airtight, water would get into the jacket in large quantities and we can't guarantee they'd dry completely if that were to happen. Our recommendation is to NOT wash them in a washing machine or use a dryer on the Insulated Jacket.

26. What about the extra head space when aging wine for 4-8 weeks?

When using FastFerment no transferring from buckets to carboys is needed so all the headspace air is pushed out during primary fermentation and it is still just Co2 in the headspace during this aging. When using buckets or carboys when you transfer to the carboy the headspace is air because it is a new container and thus reducing headspace is important to avoid oxidizing your wine.

27. Do you have suggestion for helping control the flow when bottling?

When bottling it is best to use a combination of the valve and hose clamp to control the flow rate. The conical mean there is much more pressure/force/volume than tradition racking and transferring via syphoning. We suggest when ready to bottle only turn the valve on ⅛ - ¼ of the way open to help ease pressure off the hose clamp.

28. What are the dimensions of the O-Ring?

The O-ring has an outside diameter of 35mm and the thickness of the ring is 3.5mm

29. What kind of epoxy can I use if I'd rather seal my Thermowell for good than use tape?

Many users have bought Food-Grade, HDPE safe epoxy to affix their thermowells permanently with success. We don't endorse any certain type of epoxy or recommend it, but users have reported success!

30. Do you have any suggestions for the clarifying step of doing wine?

We find that some of the higher quality kits contain cleaning agents that sometimes turn into a thicker sludge and can sometimes block the valve. Not always but sometime depending on what kit it is. We suggest two things.

- On the higher quality kits, try adding only 1/2 of the chemicals to clear it. The conical design does a superior job at filtering everything down into the collection ball that only using a portion of the clearing agents will do a great job and prevent the valve from becoming blocked. Others are having good results with this.

- Instead of using the clearing chemicals that come with the higher quality kits we suggest switching them out and using.. #5 Isinglass - Ichtyocolle (Fining Agent/Clarifiant) See pic below. Thousands of test results over many years prove this to be a great alternative.

31. How can I heat my FastFerment?

We will be coming out with a temperature control jacket for FastFerment by the end of the summer 2015. In the meantime, we have had some brewers putting a heating pad and blanket or cover around FastFerment to increase the temperature around the unit. The only thing we caution is to not create any hot spots so using a low temperature setting works best.

32. Do you have any suggestions for Lagering?

First, we have an Insulated Jacket for temperature control that you will need for Lagering. In terms of yeasts to use, we have found there a couple yeast strains that work really well for doing Lagers in FastFerment. You do not necessarily need to have traditional low temperatures for Lagering. Some homebrewers have brewed great Lagers at the mid 60’s temperature range in FastFerment. They have done this by using these yeasts.

Wyeast Laboratories: 2124 Bohemian Lager

Fermentis - SAFLAGER S-23

33. What do I do if my Union Valve is stuck together?

Sounds like the Union Valve got over tightened when installing the collection ball. If you look at the bottom of the valve when unscrewed there is a (should be) a black oring. This is the part that seals the valve and not forcefully cranking it tight.

34. Is it possible to also do a 3 gallon kit with the FastFerment, or is there too much headspace?

There is too much headspace to do a 3 gallon kit. Going up to 5-7 gallons, more brew/wine is never bad ;)

35. How is the FastFerment Union Valve positioned on the Conical Vessel?

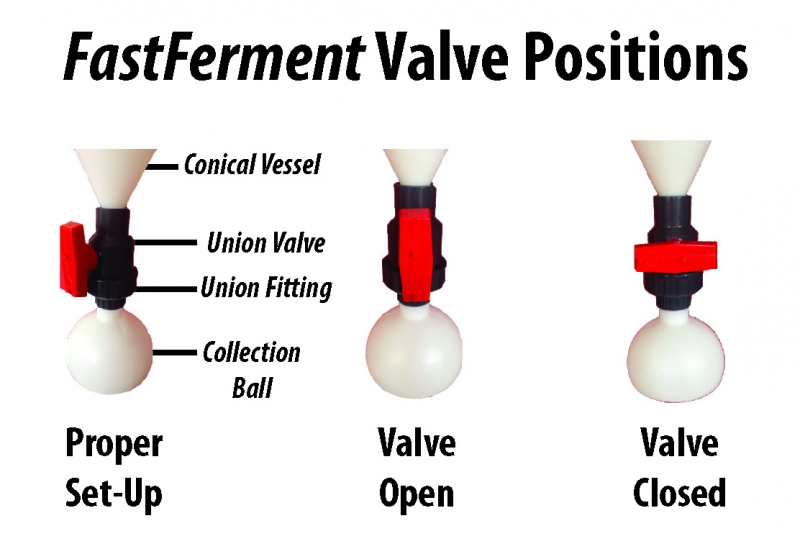

The valve is placed on the conical with the union fitting side on the bottom. It screws into the conical vessel and the union fitting is on the bottom to screw onto either the collection ball or the filling hose attachment (see picture below to show the valve positions).

36. How do I remove the Collection Ball?

When you are removing the collection ball, you should unscrew the grey union fitting collar and not the collection ball itself. When you do this, you do not need any extra vertical room to remove it as it slides directly out. Make sure to have a plate underneath the collection ball to catch any excess liquid.

37. Have you thought about a Sampling Port?

The Sample Port is here! Ask your retailer about it today - $14.99 MSRP.

38. How Do You Degas?

For wine, degas vigorously for 2-5 minutes with the valve closed. You can repeat this step 2-4 times a day over the next 2 days but doing it once really well is good enough. Our recommendation with degassing is to use an agitation wand on a drill for a minute or a plastic stir spoon. With a five gallon batch, there's very little degassing necessary because of the small volume. A degassing vaccum is not needed, however, if that is your preferred method, we have not measured the max pressure that the conical body can handle. We assume a lot less than a glass bucket and carboy.

39. I don't use the Thermowell as I use stick-on thermometers. How can I plug up the Thermowell hole?

You could try a 1/2" NPT threaded bolt to fill the hole as long as the material used to make the bolt is safe to be in contact with beer, wine...etc. You can also just leave the Thermowell in the Conical Vessel even though you may not use it since it is the perfect fit and can be Teflon Taped for a good seal.

40. Can I use fruit when brewing/winemaking in my FastFerment?

Many people use fruit in the FastFerment. Basically, keeping the pieces of fruit small (under 1" squared), so they can fall down into the collection ball without clogging is key. Then, ensuring that the collection ball is emptied mulitple times to avoid back up is important. Everybody uses a different strategy so some of it might be trial and error depending on what fruit you are using but our main tip would be to keep the pieces of fruit small.

41. How Can I take the Union Valve apart to Tighten or Clean it?

The following will allow you to properly disassemble the Union Valve. Also, if you need some extra help, use a pair of needlenose plyers

42. What is the minimum amount of Beer or Wine can you make in a FastFerment?

Based on headspace, you don't want to make anything less than 5 Gallons of beer or 5 Gallons of wine for it to turn out perfect.

43. How do you the thermometer without opening the Insulated Jacket?

The FF must be sitting in the wall mounts/stand with the measurements (Gallons & Litres) facing out so the user can read them. There is a velcro flap on the jacket you can open to see the thermometer

44. Can the FastFerment be pressurized?

The FastFerment CANNOT be pressurized, if you pressurize it, we cannot guarantee it will be damaged.

45. What is the Star San supplied in my kit - dilution ratio?

The ratio is 1oz for every 5 Gallons of water.

46. Do you have a mason jar attachment for the 7.9G?

Not currently but we expect our attachment accessory to be ready by the summer of 2018.

47. What is the ideal temperature for making Wine?

Experts say red wines should be fermented between 70 and 85 degrees F (20-30 degrees C) and white wine fermentation temperatures should be between 45 and 60 degrees F (7-16 degrees C)

48. Where can I purchase replacement parts?

Our website has a map with retailers found HERE Input your location using City or Postal Code/ZIP and stores and online options will be available.

49. What can I do if my Union Fittings are tight?

We've had some people say that if you apply a little bit of keg lube or vegetable oil to the grey fittings that they will come off a lot easier afterwards.

50. My FastFerment seems like it's not bubbling, what do I do?

When making beer and wine in FastFerment, the bubbling action is much less vigorous than traditional buckets and carboys. If however you think there is an air leaking issue, check that you're using our latest gasket - BUY HERE to ensure a solid seal. Also, check that there is nothing wrong with the threads at the top and ensure you've properly tapped the unit according to the manual.